ABOUT GAZNET

Biogas, CNG and Hydrogen mobile transport and storage solutions

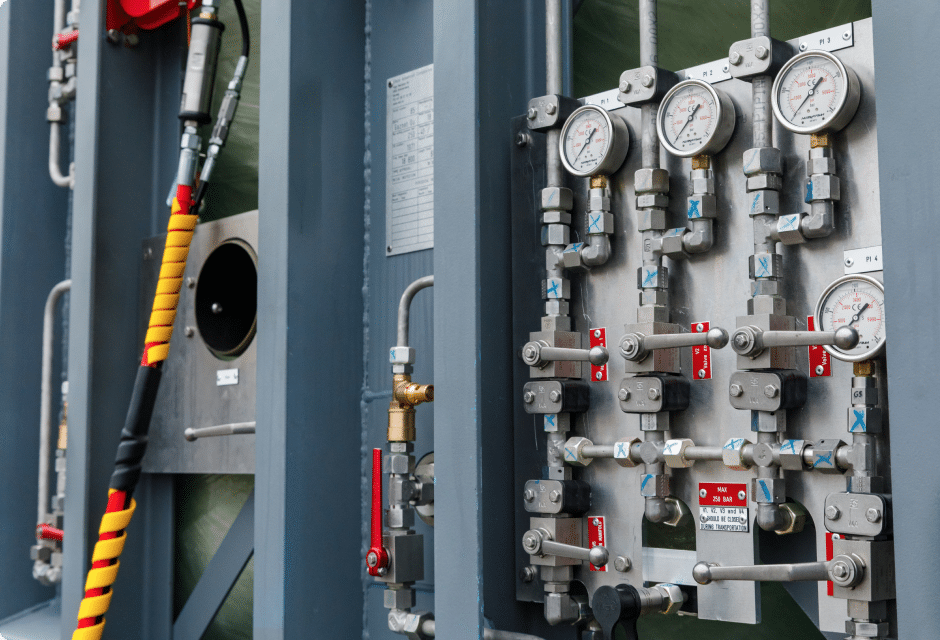

Gaznet provides advanced CNG and H2 transport and storage solutions, Compression Systems for Daughter Stations, Mobile Filling Stations, and Pressure Reduction Stations. We utilise mobile MEGC containers for filling solutions in addition to installing and maintaining gas appliances. All our applications are ADR approved and inspected.

Dedicated Teams

Our team are highly skilled professionals, committed to helping you achieve and exceed your goals.

True Partners

Every client, and each project requires an individual engineering solution and approach.

High Standards

Our CNG and H2 containers are approved in accordance with EN 12245. And far exceed the requirements of this standard.

Global Know-how

Our team is innovative, ready and capable, with the right background, experience, and understanding. Your partner in the unique potential and further advances in CNG and H2 storage and transportation.

Focus On Innovation

Biogas, CNG transport and storage solutions

The lining of our CNG container cylinders is plastic, and the end elements are made of stainless steel. Type 4 cylinders are very resistant to corrosion.

Hydrogen cylinders are produced for pressures 250, 350, 450 bar. The plastic liner has very low diffusion rate. At 2% in the year – this figure is one of the best on the market.

HOW WE WORK

Our Work Process

Reasearch & Analysis

We create CNG and hydrogen storage and transportation solutions with professionalism and expertise. You can send us a query or questions about the desired solution. When the objective is clear, we send You a draft offer with the price of the standard solution.

Creative Solutions

If the draft offer meets Your expectations, we will continue to work on a more personalised solution. Our approach is distinctly innovative. We are ready to provide You with any custom solution. We make the changes and provide project schemes and a more detailed description.

Building

After accepting the project offer we make a contract and take the advance payment. Then we start ordering the details and producing Your solution. We specially select teams for every project, to ensure each project gets the attention of the people who have the most relevant technical skills, knowledge and experience.

Project Launch

When the device is ready, we carry out tests, type approval and deliver according to the agreement. Our CNG and hydrogen containers are approved in accordance with EN 12245 and far exceed the requirements of this standard. Also, we personally come to your place and carry out the training.

Perfect Solutions For Any Industrials

OUR BLOG