Brochures

Our approach is distinctly innovative. We constantly seek new ways to increase client satisfaction.

Our approach is distinctly innovative. We constantly seek new ways to increase client satisfaction.

Gaznet is proud to introduce our state-of-the-art mobile storage solutions for CNG/Biogas and hydrogen transportation. For our gas transport containers, we are pleased to partner with UMOE Advanced Composite, a leader in composite cylinder technology. Our exclusive partnership with UMOE AC enables us to deliver unparalleled performance, reliability, and safety in natural gas containers for transportation.

We produce the Multi Element Gas Container (MEGC) for CNG and Hydrogen (H2) transport and storage. Read more about MEGC here.

Our partnership with UMOE Advanced Composite ensures that our gas transport containers meet the highest standards of quality and innovation. For CNG and biogas applications, Gaznet utilises UMOE’s advanced composite cylinders, renowned for their durability, corrosion resistance, and lightweight design. These containers are engineered to withstand the rigours of transportation and storage. And provides optimal performance and peace of mind for our customers. Customers can trust in the reliability and integrity of these containers for their CNG and H2 storage and transportation needs.

Our partnership with UMOE Advanced Composite ensures that our containers meet the highest standards of quality and innovation. For CNG and Biogas applications, Gaznet utilises UMOE’s advanced composite cylinders, renowned for their durability, corrosion resistance, and lightweight design. These containers are engineered to withstand the rigours of transportation and storage. And provide optimal performance and peace of mind for our customers.

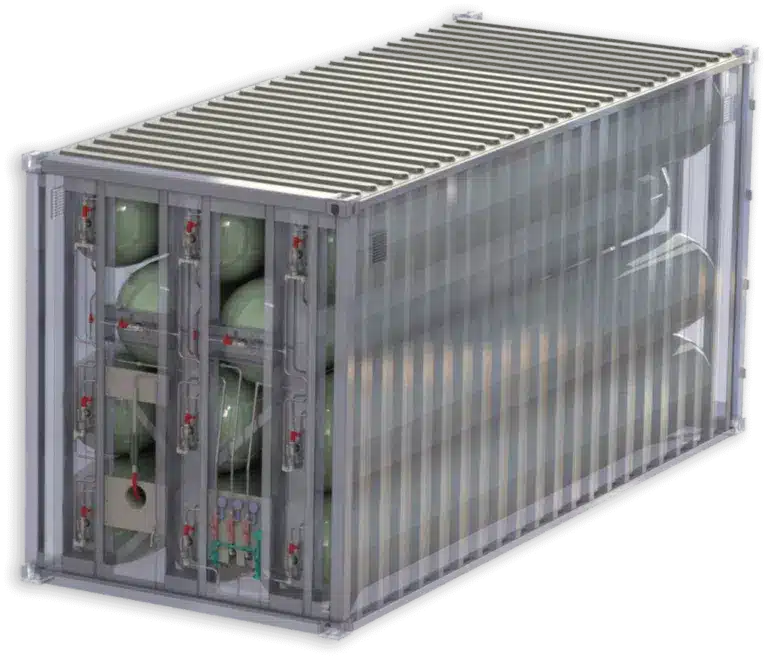

ISO 20 ft High Cube container 3D visualization

Our Natural Gas containers for transport have a plastic lining, stainless steel end fittings, and lightweight composite construction of high-strength fibreglass and epoxy resin. Low-cost type IV natural gas containers significantly reduce lifecycle costs, while preserving the quality, safety and lifetime of our products. Using such materials eliminates problems with corrosion, and also guarantees the absence of galvanic corrosion.

The CNG cylinders were tested with a safety factor from 3.2 to 3.4. They are designed for 250 bar and have a burst pressure of 840 bar or higher. Cylinders are approved in accordance with EN 12245 and far exceed the requirements of this standard. It is essential when testing for defects, impact tests and fire tests.

For operating pressures of 200 and 250 bar, cylinders of various volumes are available. Likewise, each cylinder can be up to 2400 litres and is intended for both transport and storage of CNG or BIOGAS. Tanks can be filled up to 15 000 times, giving a long-term use.

Safety is very important when transporting and storing flammable gases such as CNG under high pressure. With our solutions we deliver the ultimate safety, thanks to the material properties of fibreglass CNG Type IV cylinders and the structural design of our CNG transport containers. We subject our products to stringent fire, fatigue, stress rupture, burst pressure, impact and proof tests.

– Containers have steel or aluminium sidewalls to protect the CNG containers from external impact.

– Our natural gas containers are designed, calculated, and tested according to the requirements of ADR (standards in transporting dangerous goods).

– All type approval tests have been carried out jointly with DNV-GL and approved in accordance with TPED / ADR. Our CNG containers exceed 8 times the requirements for fire tests without any devices overpressure or heat release. Therefore, you can decide whether to equip containers with these devices or not.

Since the lining of our natural gas containers is plastic, and the end elements are made of stainless steel, type 4 cylinders are very resistant to corrosion. It is an essential factor even for small amounts of CO2 / water and/or H2S.

Composite materials utilised in the design of UAC pressure vessels for CNG transportation offer non-corrosive properties, wide temperature tolerances, high-strength fatigue durability, enhanced safety and an extended lifetime in harsh and hazardous environments. Also, our CNG containers offer up to 70% weight reduction, compared to steel cylinders.

Composite materials are highly flexible and scalable to accommodate more extensive containment and transportation of CNG volumes.

Type 4 cylinders are suitable for stationary CNG storage solutions designed for pressures up to 250 bar, with different configurations depending on the required volume. You can look at our range of mobile CNG storage solutions on the Products page.