The Shift Toward Decentralized Biomethane Production

Not every biomethane project needs to be a large, centralized plant.

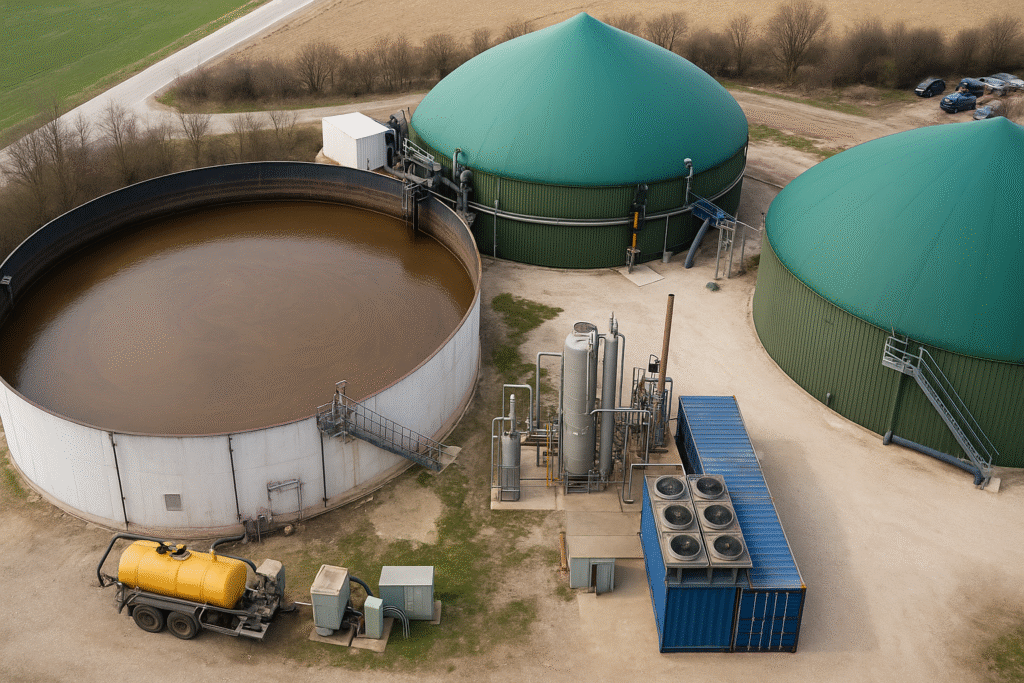

Across Europe, small to medium-sized biogas facilities increasingly produce high-quality biomethane closer to the feedstock source — on farms, at waste treatment facilities, or near industrial sites.

In particular, membrane separation is one of the fastest-growing upgrading technologies driving this shift toward decentralization.

How Membrane Separation Works

Membrane systems use selective permeability — a physical process where, as a result, different gases pass through a membrane at different rates.

-

Compression: The system pressurizes raw biogas.

-

First Pass: It pushes the gas through a semi-permeable membrane. Smaller molecules (like CO₂) pass through faster than larger methane molecules.

-

Multiple Stages: To achieve pipeline-quality CH₄ levels, the gas typically moves through two or three membrane stages, each of which further increases methane concentration.

As a result, membrane systems produce biomethane with 97%+ CH₄ content — ready for compression, storage, or injection.

-

Advantages of Membrane Separation

-

Compact Footprint: Ideal for smaller sites or locations with limited space.

-

Energy Efficiency: Particularly competitive at small to medium scales.

-

Modular & Scalable: Moreover, membrane systems can expand as production grows.

-

No Water or Chemicals: They offer a simple, clean operation.

-

Considerations and Limitations

-

Pre-Treatment Required: Operators must remove H₂S, moisture, and particles to protect the membranes.

-

Multi-Stage Investment: Achieving the highest purity often involves multiple membrane stages.

-

Fouling Sensitivity: Oils, dust, or other contaminants may degrade performance over time.

Where Membranes Shine

Membrane upgrading is especially well-suited for:

Decentralized plants without pipeline access

Projects planning gradual capacity growth

Operators seeking low-maintenance, modular systems

From On-Site Upgrading to Off-Site Use — Gaznet’s Role

When your membrane system produces clean biomethane, Gaznet’s Type IV composite MEGC containers bridge the gap between production and market:

Flexible Deployment: MEGCs can be filled on-site and transported anywhere — no pipeline required.

Cost-Effective Logistics: Their lightweight composite design helps reduce transport costs.

Regulatory Peace of Mind: ADR-approved for safe, compliant European transport.

Consequently, with membrane upgrading and MEGC transport, you can produce biomethane anywhere — and deliver it everywhere.