Brochures

With our distinctly innovative approach, we constantly seek new ways to increase client satisfaction.

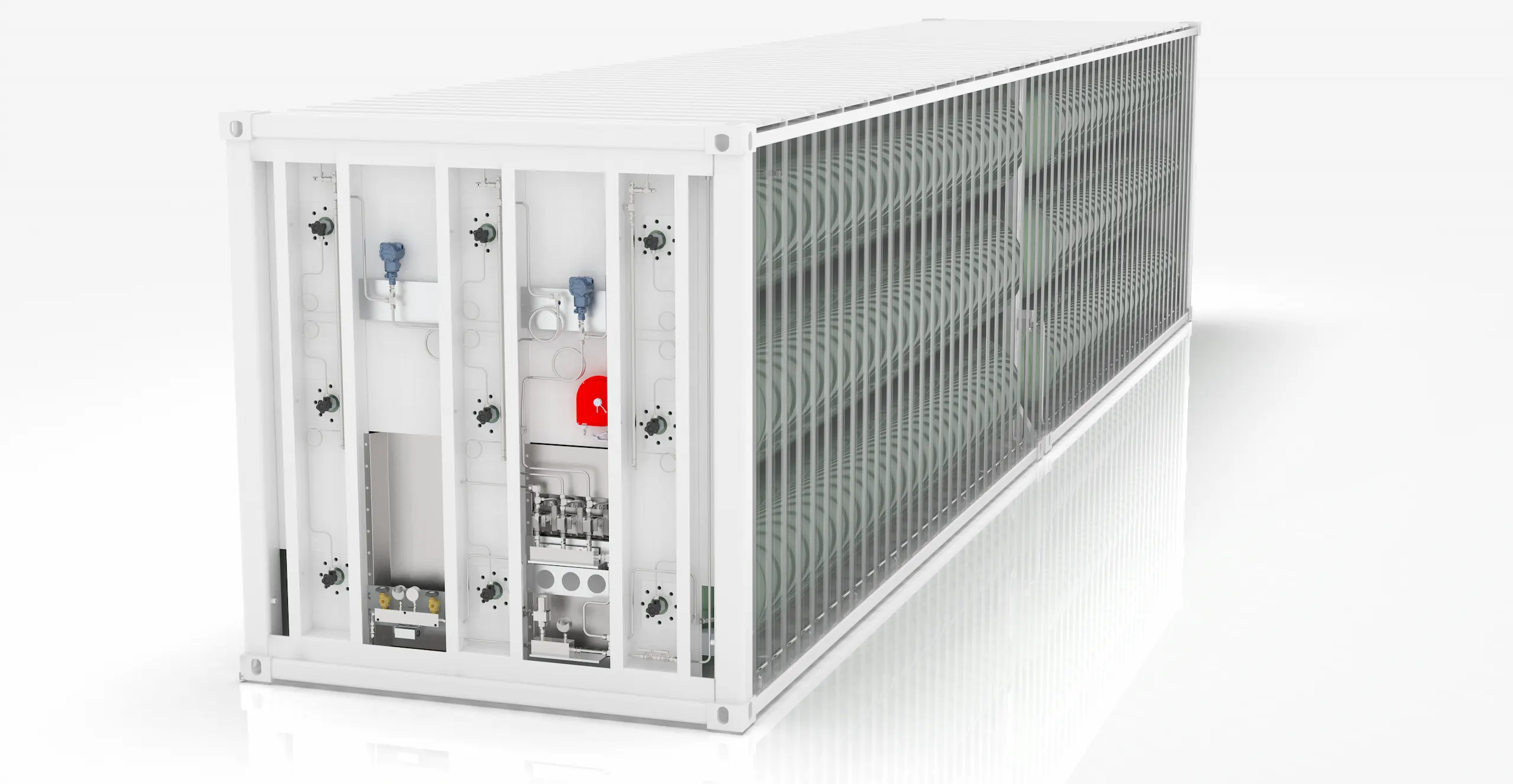

Our hydrogen transport containers modules are equipped with type IV fibreglass pressure vessels and offer the highest safety levels in high-pressure transportation of large volumes of hydrogen, combined with a competitive price per kg of hydrogen. Our hydrogen transport solutions are type-approved according to EN 12245, ADR and TPED. Both hydrogen and CNG transportation containers far exceed EN 12245 the standard requirement, because it is essential when testing for defects, impact tests and fire tests.

Hydrogen transport container

Our hydrogen transportation containers are lightweight, robust and non-corrosive. They offer excellent fatigue durability, wide temperature tolerances, increased safety and cost-efficiency. We supply standard configurations and tailored solutions to meet specific customer requirements and regulatory standards.

H2 transport container

We present the ultimate H2 transport container. Our hydrogen transport containers are UAC pressure cylinders, with a minimum safety level of 3.0. We apply rigorous testing in fire safety, automated fatigue, stress rupture, burst (up to 1,600 bar), impact, and proof testing. Such comprehensive testing exceeds industry standards. Providing our customers with unparalleled reliability and safety. In addition to meeting rigorous safety standards, UAC pressure cylinders provide wide temperature tolerances (-40°C to +65°C). Also excellent fatigue properties, durable lifetimes, and high safety levels compared to steel and carbon-fibre solutions. We believe, and the evidence shows, that fibreglass pressure vessels represent a cost-effective alternative to carbon fibre cylinders.

Hydrogen containers that offer flexibility, efficiency and safety

Weight reduction

Type IV pressure vessels in robust fibreglass for hydrogen storage offer up to 70% weight reduction compared to steel skids.

Non-corrosive and non-toxic properties

Our hydrogen and CNG Type IV cylinders have a plastic lining, stainless steel end fittings, and composite construction of high-strength fibreglass and epoxy resin. Using such materials eliminates problems with corrosion, and also guarantees the absence of galvanic corrosion. The cylinders were tested with a safety factor from 3.2 to 3.4. They are designed for 250 bar and have a burst pressure of 840 bar or higher.

Non-toxic and non-corrosive properties of our pressure vessels for hydrogen transportation benefit the lifetime of solutions by eliminating the risk of galvanic oxidization. Weight savings, temperature tolerances, long-term design life and enhanced safety levels offered by glass fibre pressure vessels challenge alternative solutions in steel or other composite materials.

Safe and durable hydrogen transportation solutions

– Larger hydrogen gas volume and high-strength durability. Storage capacity of 600 – 2 400 litres per pressure vessel. Storage capacity of up to 42 350 water volumes per hydrogen container. Pressures up to 350 bar.

– Superior safety levels. The hydrogen cylinders were tested with a safety factor from 3.2 to 3.4.

– Extended service lifetime and reduced lifecycle cost. Using our hydrogen and CNG containers you get a guaranteed high-performance utilization and a profitable lifetime of our solutions, contributing to the cost-effectiveness. Investment in high-pressure hydrogen storage and transportation solutions can be high, which is why we offer our clients durable solutions in hydrogen and CNG storage and transportation.